|

| Selecting bamboo to make the skeletal framework of folding fans__Photo: saigoneer.com |

Located about 30 kilometers from the center of Hanoi, Chang Son is a typical wet rice farming village in the north of Vietnam but it has long been well-known for the craft of making folding fans.

It is noted in the local history that the fan-making craft appeared in the village hundreds of years ago. Originally, Chang Son villagers made fans as a side hustle in their leisure time. The craft reached its peak in the 19th century when folding fans produced by Chang Son villagers became popular to people all around the country and were even brought to an exhibition in Paris. In the age of modern electric fans and air conditioners, it appeared that the craft would fall into decline but Chang Son villagers had tried their best to maintain and promote their tradition.

|

| Paper is glued on the skeletal framework__Photo: saigoneer.com |

Late artisan Duong Van Mo (born in 1935), was credited with having restored the folding fan-making craft, turning Chang Son fans from ordinary personal belongings to decorative items of high artistic value.

The artisan spent much of his time and efforts repairing and restoring antique fans, some of which were seriously devoured by termites, so as to seek, maintain and develop the most quintessential features of the craft.

On the occasion of the Millennial Anniversary of Thang Long-Hanoi in 2009, artisan Mo, together with some other fan makers in Chang Son village, succeeded in making a huge fan which was 9 meters in width and 4.5 meters in height, featuring the scene of a market in the ancient Hanoi. It was recognized by the Vietnam Records Book Center as the biggest-ever paper folding fan in Vietnam.

Chang Son fans now have a variety of designs and sizes. Paper fans are usually decorated with drawings or calligraphy writings, while fabric fans are embroidered or have embroidery added between two layers of fabric.

|

| Artisan Duong Van Doan__Photo: hanoitimes |

“It takes many steps to make a folding fan in which all are done manually. To make a beautiful product, the craftsman must be careful at each step”, said Duong Van Doan, the son of artisan Duong Van Mo.

Bamboo for making fans must be termite-free and of a decent age. After bamboo piles are cut to the desired length, they will be soaked in water for four or five months to become more durable and elastic.

|

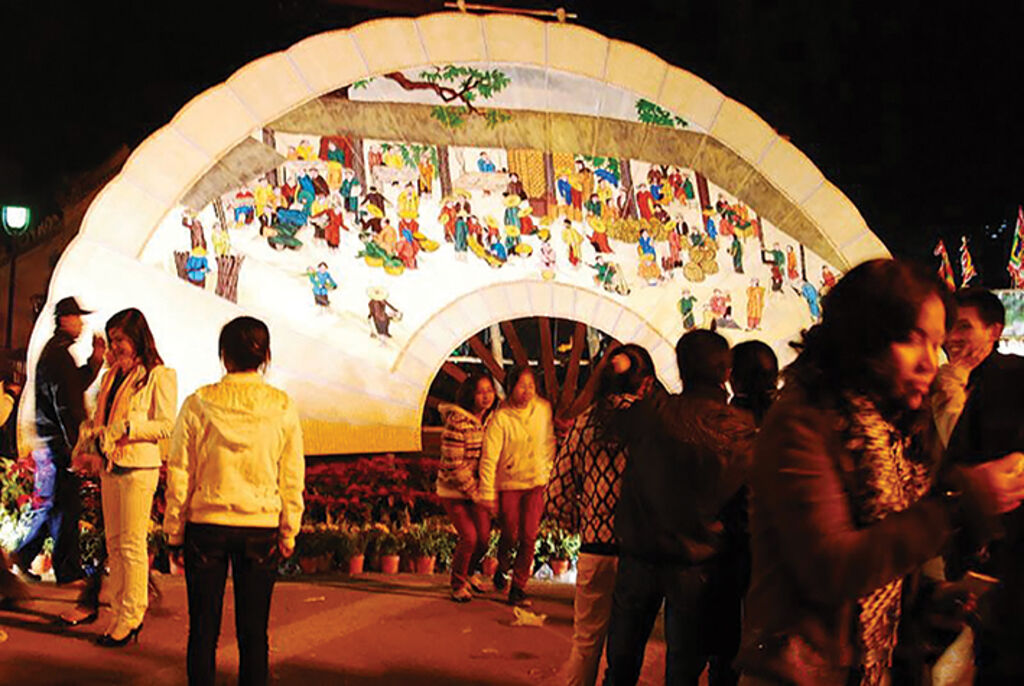

| A nine-meter-wide fan displayed at the Hanoi Flower Festival during the 1,000th anniversary of Thang Long-Hanoi__Photo: iamvietnamese.vn |

After that, the bamboo piles will be trimmed into thinner sticks which will be nailed through and bent into an arc shape to create the skeletal framework of the fan.

One of the most difficult stages of fan making is to glue paper or fabric on two sides of the bamboo sticks to make the loop of the fan. It requires meticulous efforts to ensure that the layers are crinkle-free, even when the fan is folded.

|

| Paper fans of different types and sizes sold in a shop in Chang Son village Photo: hanoitimes.vn |

In the past, most Chang Son fans were made from poonah paper but today assorted types of papers and fabrics are used. Similarly, industrial adhesives are used, instead of persimmon fruit gum, for gluing paper on the skeletal framework.

“Today, no one says fan making is just a side hustle”, said artisan Doan, adding that many families in Chang Son village earn their living from the craft, selling tens of thousands of fans to the market every day.-