|

| Photo: Tran Viet/VNA |

Located in Chuyen My commune of Phu Xuyen district, about 32 kilometers south from the center of Hanoi, Chuon Ngo village is well known for the traditional intricate craftsmanship of mother-of-pearl inlay.

Legend has it that the craft of mother-of-pearl inlay, also known as nacre inlay, was passed on to Chuon Ngo villagers by Truong Cong Thanh (1053-99), a mandarin of the Ly dynasty (1010-1225). After helping General Ly Thuong Kiet defeat the Sung aggressors, he returned to the village and taught the villagers how to insert pieces of mussel and snail shells into wooden objects to create handicraft items. During the feudal period, Nguyen Van Phuc, Ly Muc and other Chuon Ngo artisans were invited to the Hue Imperial Citadel to produce various mother-of-pearl inlay objects, ranging from tableware to furniture, for the Royal Court. As time passed, generations of the Chuon Ngo village strived to preserve their millennium-old craft and their love for the craft is passed on to their descendants. Nowadays, on the ninth of the first lunar month, villagers hold an incense-offering ceremony in Truong Cong Thanh’s temple to show their gratitude and respect to the ancestor of the traditional mother-of-pearl inlay craft.

|

| Abalone shells - best raw material for inlay products__Photo: Viet Anh/Vietnam+ |

“Mother-of-pearl inlay is a craft that requires patience, dexterity, meticulousness and the passion for it,” national artisan Nguyen Dinh Hai, who is the owner of a mother-of-pearl inlay workshop in the village, told the Vietnam Law & Legal Forum magazine.

Making a nacre inlay product is a labor- and time-consuming process. It comprises various steps from material selection, designing, drawing, sawing, inlaying, carving and polishing.

The process begins with the selection of raw materials. Mussels and sea snail shells are traditional sources of materials for crafting nacre inlay products. To enrich their products’ colors, Chuon Ngo villagers also use shells of silver-lipped pearl oysters (Pinctada maxima) and other different types of oysters from various parts of the country as well as abalones imported from Hong Kong (China), Indonesia and Singapore. Among the imported raw materials, red abalone shells, with abundant shades of red, are considered the best.

|

| Sawing shell based on designed pattern__Photo: Kieu Trinh/VNA |

The next step is making flat seashell slabs. In the past, Chuon Ngo villagers used to chisel raw seashells along the grains to peel off their outer layers. Today, modern machines are used to carve off both outer and inner layers, leaving the pure middle layers. These layers are later cut along the curvature to get slabs of different sizes, which are then placed between thick steel sheets in water and gently flattened little by little until they are as flat as papers.

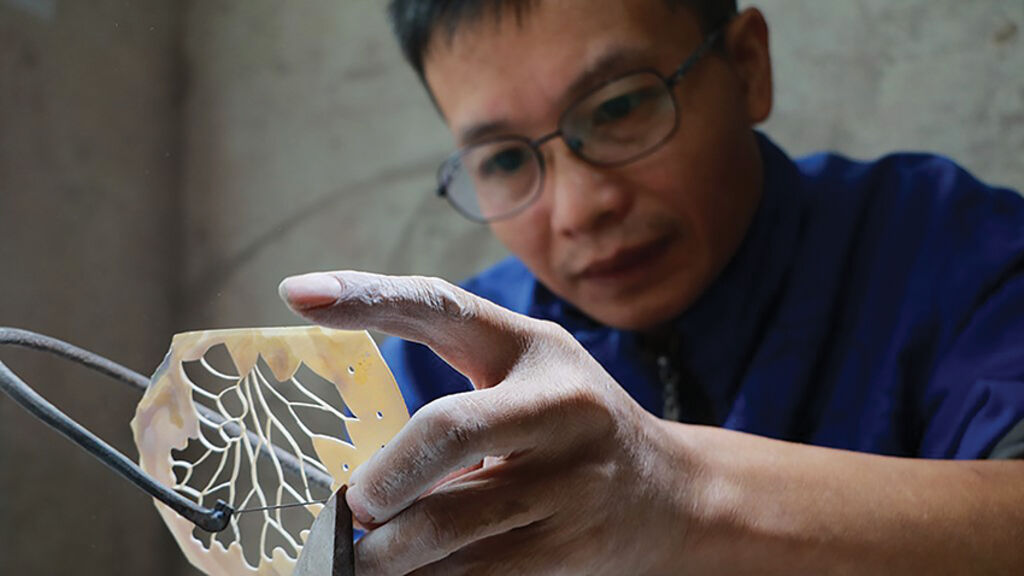

The craftsman will base on designed patterns to select suitable seashell slabs and then saw them into desired shapes. In order to saw tiny details of exquisite patterns such as chrysanthemum petals, butterfly legs, bee legs and shrimp antennae, the craftsman uses a special saw with the blade made from a hairspring. This step demands exceptional patience, skillful hands and great attention as a single nacre inlay product may consist of thousands of fragile nacre pieces.

|

| Roughly assembling shell pieces on wooden surface, marking their positions before carving__Photo: Tran Viet/VNA |

After that, the pieces are roughly assembled and attached to the dry wooden surface with rice paper glue and their positions are marked in order to provide a clearer picture of what the finished product will look like. Once completing the carving, the craftsman applies layers of sap extracted from the wax tree, Rhus succedanea, a native plant grown in Phu Tho province, to a side of the seashell pieces and embeds them in the wooden surface.

The process continues with the wax tree sap applied to the outer lines of intricate patterns. The craftsman then uses a tanto blade knife to carve these lines to highlight the vivid details. The wooden surface is subsequently polished with sandpaper.

|

| Chuon Ngo nacre inlay products__Photo:hanoi.gov.vn |

Chuon Ngo mother-of-pearl inlay products are diverse, ranging from horizontal boards and pairs of parallel sentences hung in pagodas and temples, furniture, home decors and utensils to portraits.- (VLLF)